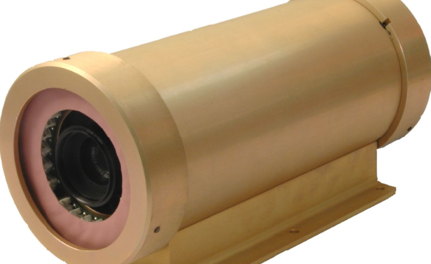

PROMON SCOPE, the complete easily operated, high speed video camera for industrial bottling and packing applications.

Today’s production facilities can only produce goods profitably if the production processes can be optimized, and if downtime and material wastage can be reduced. AOS Technologies presents PROMON SCOPE, a system, which has for the first time, been specifically developed for industrial process analysis via high speed camera.

The performance characteristics of the PROMON SCOPE are practically oriented, and the sturdy design guarantees a long service life, even in a hard, every day industrial environment. The PROMON SCOPE high speed video camera records bottling processes continuously without interruption, and enables critical sections to be played back, and evaluated immediately in extreme slow motion, or in individual images. In this way, any discrepancies, causes of errors, incorrect settings and wear, are immediately visible and comprehensible.

PROMON SCOPE stamps every individual picture with a date and time, accurate to the millisecond, enabling the image date to be easily compared with other recordings. With the understanding gained in this way, optimizations to the industrial bottling process can be systematically identified and implemented. A complete range of accessories means that the system can be deployed without any further purchases, and the high speed camera is virtually immediately ready to shoot.

The controls are ground-breakingly simple. Recording is started, and the whole system is controlled with just a few clicks on the touchscreen. With the PROMON SCOPE, for the first time it is even possible to record, visualize and archive the stages and wear levels of any commercial bottling system in operation at full process speed. Service intervals can be scheduled precisely as required, bottling system availability is increased, and unnecessary maintenance can be avoided.

PROMON SCOPE permits the effectiveness of the measures taken, to be verified immediately. Time consuming approximations to the final solution are avoided. Image data can be easily exported in standard formats, and viewed, edited and archived on any PC.