Thank you Kvalitest for sharing this with us!

In today’s top sports, the training of athletes is strongly based on the results of testing and measurements. This is also the case with the Finnish ice hockey league (Liiga), where even the performance of an individual player during the regular season is monitored and strain is optimised by measuring many different things.

The performance of these fully tuned-up athletes is monitored and optimised just like with industrial machines and processes. And in hockey today, points of interest from the perspective of the viewer are measured, such as the skating speeds of the players, the distances skated, and even the speed of the puck.

Kvalitest Industrial followed the Liiga regular season this year with interest and especially JYP Jyväskylä. This season, Antti Kalapudas, who became a new centre for the team and a player sponsored by Kvalitest in December 2019, was under special observation. For example, the gold medal from the 2016 U20 World Junior Ice Hockey Championships can be found in the trophy case of this young and promising forward!

In recent years, those who follow hockey have not been able to avoid the hype about Patrik Laine’s shot and the development of shots in general through the high-paced progress of composite hockey sticks. Today’s composite hockey sticks have transformed shooting into a technical sport, when compared to the time of the wooden sticks of Torspo and others, which were stiff like iron bars. With today’s hockey sticks, even light-weight players can shoot the puck at high speeds.

So, we decided to organise a shooting competition: Liiga player Kalapudas vs. sales engineer Laurikainen at the LähiTapiola Arena.

How important is technique for the flex of a stick during a shot?

We supply our industrial customers with sensors and measurement solutions, for measuring, for example, acceleration and the flex of the sticks. So, we were interested in measuring the shaft flex of the sticks and the acceleration of the blade during the shot.

It also made us start to wonder the difference that is made by the technique. This can be seen, of course, when comparing the shots of two people of approximately the same size (height & weight), one of whom is a professional hockey player and the other who sells products and solutions for a wide range of industrial measurement needs.

Preparing the hockey stick

The flex of the hockey stick is measured by the Kyowa strain gauge sensor. The function of the strain gauge sensor is based on a change in resistance. Simply explained, the resistance of the strain gauge sensor changes when its structure stretches, compresses, or twists along the surface to which the strain gauge sensor is attached.

As the resistance of the strain gauge sensor changes, the voltage measured over the measuring bridge also changes. The voltage signal can therefore be used to measure the stretch, compression or twist of the structure with the sensor. The voltage signal is converted to a readable form and unit when measuring. In this project, the signal was read using Teac’s portable hand meter.

The optimal place for measuring the flex would be the point where the stick shaft bends the most. But since we also wanted to compare wrist shots and slap shots with each other, where the maximum flex position may vary, we ended up attaching the strain gauge sensor to the top of the shaft. The point on the shaft that is also, in principle, the most protected. The strain gauge sensor was attached by glue and protected with tape.

Calibration of the strain gauge sensor

The strain gauge sensor was calibrated compared to the force exerted (N, newtons) on the shaft of the stick. The material testing machine (CS2-1kN) at the Kvalitest Industrial Test Centre was used for calibration, which they used to bend the stick at three different levels of force, according to which the strain gauge sensor was adjusted to match the force used to bend the stick at each level.

In this project, it was decided to measure the acceleration of the blade with the MSR 175 wireless data logger, which measures acceleration and environmental conditions, and which has been used more generally to monitor vibrations and changes in conditions during transportation.

This time, we were only interested in acceleration

The device records the accelerations that are measured, and the data are extracted to a computer where they are ready for immediate analysis after measurement.

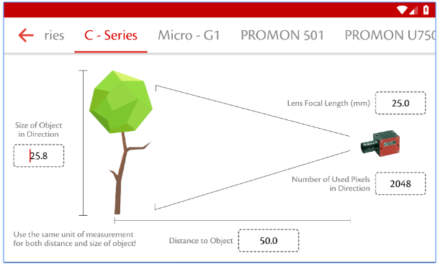

A high-speed camera for recording high-speed events

In addition, we included our high-speed camera, which is a great tool for accurate visual analysis of high-speed events. We had time to shoot Antti’s shot with a camera giving a great picture of how the shaft of the stick and blade behaved during the shot. Read more about high-speed cameras here »

See the image of the shot with the high-speed camera below. For shooting this we used the AOS L-VIT2500 high-speed camera.

Then the actual results of the measurements!

Both shooters took three slap shots and three wrist shots. The flex of the sticks and the acceleration of the blades are shown in the table below. The shooters were sales manager Marko from Kvalitest against the company-sponsored Antti Kalapudas.

The results clearly show a difference in the flex of the sticks

With wrist shots, the flex of the stick is a strong factor for producing the initial velocity of the pucks, and the acceleration of the blade does not increase as high as with slap shots.

With slapshots, at least with these guinea pigs, there was less flex in the stick, but the acceleration of the blade was significantly higher. The impact with the puck always produces a shock-like hit on the sensor; it has been our aim to limit this hit from the results.

Unfortunately, we couldn’t get a radar to measure the speed of the puck, which would be relevant to the further analysis of the data. It should be noted, however, that Antti’s shots were clearly harder than Marko’s shots with the naked eye, which is also supported by better use of the flex in the shaft of the stick and the faster acceleration of the blade.

Perhaps next time we will have Wisehockey’s smart puck, radar, and Patrik Laine, who I mentioned at the beginning.

Text: Marko Laurikainen

You can see the shooting competition video, which was filmed and implemented by Jiri Halttunen, here in its entirety:

Thanks again JYP and Antti!

Kvalitest Industrial Oy is an experienced technology supplier offering high-performance testing and measuring equipment and solutions for Nordic research, industrial production, and service traffic.